PRODUCTION

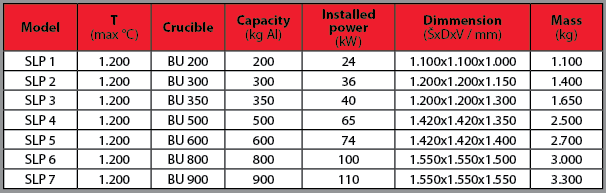

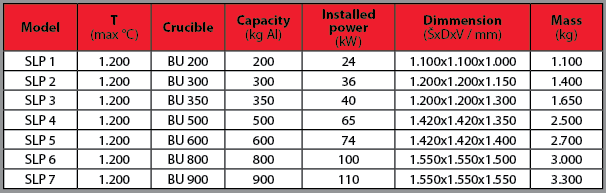

Stationary furnaces

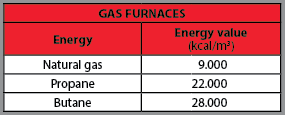

Stationary pot furnaces for aluminum, zinc alloys and other non-ferrous metals have found great application due to their practicality, easy mobility, small dimensions, the type of energy used to heat the furnace, as well as low product prices.

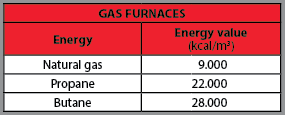

These furnaces can use energy sources such as gas, electricity and oil, in accordance with the wishes, needs and possibilities of the customer.

Working temperature is 900 °C, maximum 1.200 °C.

Furnaces have systems for regulating and monitoring the temperature of the furnace wall and the temperature of the molten metal.

Electric and flame panels furnaces have maximum energy efficiency. They are ideal for melting metals and maintaining molten metal due to low energy consumption. In the case of furnaces powered by electricity, a thyristor-controlled power supply is installed.

Stationary pot furnaces for aluminum, zinc alloys and other non-ferrous metals have found great application due to their practicality, easy mobility, small dimensions, the type of energy used to heat the furnace, as well as low product prices.

These furnaces can use energy sources such as gas, electricity and oil, in accordance with the wishes, needs and possibilities of the customer.

Working temperature is 900 °C, maximum 1.200 °C.

Furnaces have systems for regulating and monitoring the temperature of the furnace wall and the temperature of the molten metal.

Electric and flame panels furnaces have maximum energy efficiency. They are ideal for melting metals and maintaining molten metal due to low energy consumption. In the case of furnaces powered by electricity, a thyristor-controlled power supply is installed.

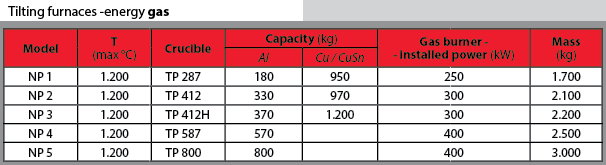

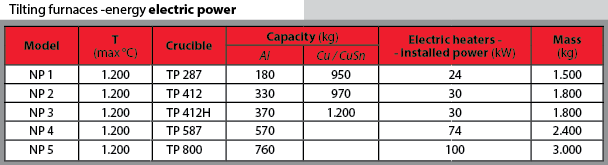

Tilting furnaces

Our tilting furnaces are completely automated, easy to operate.

They are made in an octagonal, circular or rectangular shape. The circular or octagonal concept guarantees the correct distribution and utilization of energy, as well as easy discharge of molten metal together with the unit that is right next to the furnace. The hydraulic system with two cylinders (more if necessary) enables easy tilting of the furnace, ie safe control of the solution discharge, which enables handling safety for technicians.

Working temperature is 900 °C, maximum with electric energy or gas is 1.200 °C, ie. with oil 1.300 °C.

Furnaces have systems for regulating and monitoring the temperature of the furnace wall and the temperature of the molten metal.

Electric and flame panels furnaces have maximum energy efficiency. They are ideal for melting metals and maintaining molten metal due to low energy consumption. In the case of furnaces powered by electricity, a thyristor-controlled power supply is installed.

Steel heat treatment furnaces

In furnaces for heat treatment of steel, all thermal processes can be performed: annealing, hardening, tempering, improvement.

We make steel heat treatment furnaces in the following designs:

1. Chamber furnaces – small

2. Chamber furnaces - big

3. Chamber furnaces with wagon

4. Foldable furnaces from panels

5. Flow furnaces

Furnaces can also be manufactured to work in a protective atmosphere, and for annealing they have refractory steel chambers.

The entry of the batch into the furnace can be manual, semi-automatic and automatic (on wagons, forklifts, etc.). Automation can control batch lifting, door opening, etc. Our technical staff will help you choose a stove with accompanying equipment, which would suit your process.

After entering the batch, or the material being processed thermally, the automatic process starts.

All our heat treatment furnaces have a system of automatic process management characterized by ease of use, with the option of monitoring and documenting the process. A large number of temperature changes can be set/entered, which allows the process to run smoothly, from heating or to temperature maintenance.

All furnaces can be produced to use electricity or gas as energy sources. Thyristor power supply guarantees lower consumption, for electrically heated furnaces, and easier process control (heating, cooling, maintenance ...) with software management ( forming of the heating curve), as well as the unique way of transmission, maintenance and control of heat in our furnaces, reduces energy consumption.

The operating temperature of these kilns is up to 1,150 ° C ± 2 ° C, or the set temperature varies from the type of thermal process that is applied.

Panel furnaces

Panel furnaces for thermal processing are a unique product on the market and they were created as a need for users for non-standard batches, for users who thermally process semi-finished products of different dimensions, variable quantities of batch, technical characteristics of the factory space in which the furnaces should be stored etc. For the above reasons, the customer is allowed to assemble the panels and change the working volume of the furnace, depending on the needs that occur in the production.

All this has enabled the user to set up energy consumption according to the needs of the given process, to adjust the furnace to its specific process.

Panel furnaces can quickly change the shape of the furnace, for example, a “vertical” oven for specific batch can be made very quickly to a “horizontal” oven. Change makes the consumption of energy products adjustable for precise production, and can easily adjust the furnace to your needs of the current process.

The management and software used is user-oriented and it is very easy on the control box to change the working conditions of the process, memorize more processes, and quickly set the process conditions as required.

Flow furnaces

They can be applied in drying, preheating, improving, burning, vulcanizing and other processes. They are also suitable for batches that have specific and / or small shapes.

The batch can be added manually or sprayed automatically onto an endless strip of flow furnaces. Strip speed, process curve, as well as monitoring and later process documentation are performed automatically via software, where time and temperature cycles can be easily defined.

The furnace dimensions correspond to the customer’s requirements, while the furnace cover can be lowered manually or automatically over an endless strip.

Endless strip is made of materials that correspond to the thermal process and the type of batch to be processed, both by type of material and by shape and dimension. It can be of full material or as a net.

As the other furnaces for thermal treatment, type of energy is buyers choice: electricity and gas, with direct and indirect flame.

The maximum temperatures that can be reached are up to 1,150 ° C.

Aluminium heat treatment furnaces

The aluminum heat treatment furnaces are made in two basic designs: chamber and flow furnaces. The principle of functioning is similar.

Batch input can be manual, semi-automatic and automatic (on wagons, forklifts, etc.). Automatics can control the raising of the batch, opening the door, etc. Our technicians will help you in selecting a furnace with accompanying equipment that would fit your process.

All our heat treatment furnaces have a system of automatic process management characterized by ease of use, with the option of monitoring and documenting the process. A large number of temperature changes can be set/entered, which allows the process to run smoothly, from heating or to temperature maintenance.

All furnaces can be produced to use electricity or gas as energy sources. Thyristor power supply guarantees lower consumption, for electrically heated furnaces, and easier process control (heating, cooling, maintenance ...) with software management ( forming of the heating curve), as well as the unique way of transmission, maintenance and control of heat in our furnaces, reduces energy consumption.

The operating temperature of these furnaces is up to 530 ° C ± 2 ° C, or the set temperature varies from the type of alloy that is thermally treated.

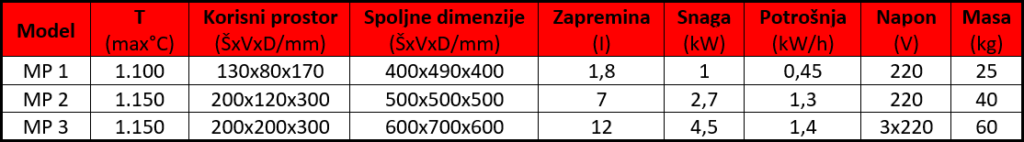

Laboratory furnaces

Laboratory furnaces are intended for thermal testing in laboratories. They are mostly used in food, chemical, rubber, plastic industry ...

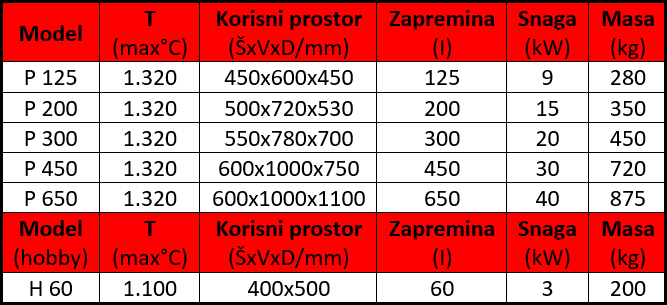

The oven is made of decorative stainless steel or material by the customer’s choice. Furnaces are produced in three models, but other dimensions are also required upon request. The maximum operating temperature for laboratory furnaces is up to 1420 ° C, on request.

Laboratory stoves have the ability to connect to a PC, to have software for process monitoring, as well as documenting or printing data.

Furnaces for Porcelain & Ceramics

Porcelain and ceramic ovens are intended for the drying and thermal process of porcelain and ceramic products, as well as processes of various sintering.

They are produced as chamber and as hobby furnaces and use electric energy as source.

Chamber furnaces are made in several dimensions, according to the dimension of the customer requires. The furnace interior is made of materials that are not carcinogenic and which do not transmit harmful effects on the batch. The distribution of heaters is on the walls of the furnace, which causes an even distribution of heat. It allows the products to dry and bake which reduce the chance for firing or deforming of the products. Heat control via software enables precise operation and process monitoring. Maximum operating temperatures are 1,300° C. In the case of large-scale furnaces, models with wheelchair have heaters in themselves.

The hobby furnaces are made of circular or octagonal shape, of small dimensions. They are suitable for manual manufacture, artists and hobby masters. These ovens are easily mobile, easy to operate and use and these are suitable for single product or fewer series production.

Dryers and painting lines

Line for painting

Depending on the quantity of the product and the type of material from which it is made, the dryers will have a different technical and technological solution in terms of the appearance and manner of the drying process.

Due to all of this, our dryers have found application in various fields in the industry. They are used in technological processes in the food and agricultural industry, as part of the chemical, metallurgical industries and in laboratories.

Heat control is automated, guided by software.

When choosing a dryer, it is necessary to pay attention to the factors related to the type and quality of the dried material, the technological requirements in the process itself, the production requirements and the final quality of the product that is required.

Painting lines – flow lines for electrostatic painting have found their application in the process of automatic painting of large quantities of products. They are characterized by the uniform quality of the application of protective material (paint, plastic, etc.) glossy or matt-free surface, absence of mechanical impurities on the product, fast drying, lack of moisture, which contributes to faster process completion and quality final product.

In the process, the speed of painting, the amount of paint application, furnace temperature, amount of remaining color in the tank, can be defined and monitored, also the other needs of the process that the customer can request.

Anti-Corrosion Protection - Heaters

Anti-corrosion protection is a very important segment in metal processing. It represents the electrochemical protection of the metal surface, which due to technological needs is exposed to aggressive (corrosive) working environment.

This type of protection is almost mandatory in environments where there is a high amount of moisture, fog, oxidation risk, as well as environments of saturated air with other agents (eg, chemical substances, etc.).

Depending on different technical and technological processes, we are producing systems for anticorrosive protection of metal surfaces with a layer of nickel, zinc, chromium and other.

Depending on the needs of the products, complete lines or segments, that is, elements that are defined in the customer’s request.

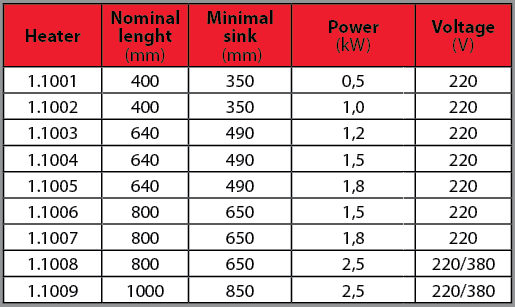

Galvanic heaters represent specific heating elements that have found their application in other technological processes, in addition to anti-corrosive protection. They are used to heat mediums which are aggressive according to the heat source material.

Probes - Thermocouples - Thermoregulation

Probes and thermocouples are used for precise temperature measurements in the chemical, metallurgical, food processing, rubber, plastics industry etc.

Measurement range is -50 to 1600 °C.

Merni opseg je -50 do 1.600°C.

Thermocouples are produced in wire thickness of ø3.26 mm. For all thermocouples, the “A” connection head according to DIN 43729 (SILUMIN) is supplied.

We also produce nonstandard probes and thermocouples where the customer delivers either a sample or sketch for making.

When placing the customer’s request, the number of thermocouples (1 or 2), ie the thickness of the thermopar (0.5 mm or 0.35 mm wire) must be specified.

We produce and coil thermoelements in the lengths 330, 500, 570 mm.

Thermoregulation is an important segment in the systems we produce. The accuracy is defined by the technological process and the customer’s request. This allows us to offer adequate thermoregulation elements so that the client and user in the production process can more easily define, control and monitor the process, and finally document the obtained parameters.

These devices are a prerequisite for quality guidance, tracking and documenting processes, as well as later precise analyzes.